ZG15ATC is 15% glass fiber toughened PA6 resin for injection molding. It offers high strength and modulus.

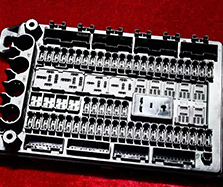

This product is mainly used in automobile, electrical components,mechanical equipments,etc.

| Properties | Standard | Condition | Unit | Typical Value | |

|---|---|---|---|---|---|

Physical |

|||||

| Density | ISO 1183 | 23°C | g/cm3 | 1.243 | |

| Melt Flow Rate | ISO 1133 | 260°C, 5kg | g/10min | 20 | |

| Molding Shrinkage(parallel) | ISO 294 | 23°C, 48hr | % | 0.6-0.9 | |

| Mold Shrinkage(transverse) | ISO 294 | 23°C, 48hr | % | 0.9-1.1 | |

Mechanical |

|||||

| Tensile Strength | ISO 527 | 10mm/min | MPa | 110 | |

| Elongation at break | ISO 527 | 10mm/min | % | 7.2-7.8 | |

| Flexural Strength | ISO 178 | 2mm/min | MPa | 155 | |

| Flexural Modulus | ISO 178 | 2mm/min | MPa | 4500 | |

| Notched IZOD Impact Strength | ISO 179 | 5.5J, 23°C | kJ/m2 | 17 | |

Thermal |

|||||

| Melting Point | ISO 11357 | DSC, 10℃/min | °C | 220 | |

| Heat Deflection Temperature | ISO 75 | 120°C/hr, 1.80MPa | °C | 195 | |

Other Properties |

|||||

| Surface resistivity | ASTM D257 | 23°C | Ω | ≥10^12 | |

| Flammability | UL-94 | 1.6mm | Class | HB | |

| General Guidelines | Value | Unit | |||

|---|---|---|---|---|---|

| Drying Temperature | 80 | °C | |||

| Drying Time | 2~4 | hour | |||

| Maximum Moisture Content | 0.1 | % | |||

| Melt Temperature | 260~290 | °C | |||

| Mold Temperature | 60~100 | °C | |||

1. The information submitted herein is authentic. It is based on our current knowledge and experience, and on the tests carried out in our laboratories.

2. The data herein is typical and not to be construed as specifications. In view of the many factors that may affect processing and application, this information is intended to be used only as a guideline for product engineer. Observation on a “trial and error” basis may be required to achieve desired results.

3. Pigments can affect properties, so unless otherwise specified, all data listed is for natural colored materials.

4. Material shrinkage data summarized in this sheet is tested from shrink plate which is specified by state standard and some difference exited compared with molding shrinkage. So the date could be used as reference only for the mold design.If you need more detail information of material shrinkage data, please don't feel any hesitataion to contact us.

5.The information will be updated along with accumulating of our knowledge and experience, please contract us timely to get the latest version.