CG30A is 30% glass fiber reinforced PA66 resin for injection molding. It offers high strength and modulus.

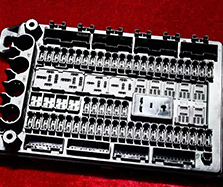

This product is mainly used in automobile, electrical components,mechanical equipments,etc.

| Properties | Standard | Condition | Unit | Typical Value | |

|---|---|---|---|---|---|

Physical |

|||||

| Density | ISO 1183 | 23°C | g/cm3 | 1.37 | |

| Melt Flow Rate | ISO 1133 | 260°C, 5kg | g/10min | 16 | |

| Molding Shrinkage(parallel) | ISO 294 | 23°C, 48hr | % | 0.3-0.6 | |

| Mold Shrinkage(transverse) | ISO 294 | 23°C, 48hr | % | 0.6-0.9 | |

Mechanical |

|||||

| Tensile Strength | ISO 527 | 10mm/min | MPa | 180 | |

| Elongation at break | ISO 527 | 10mm/min | % | 2.8-3.5 | |

| Flexural Strength | ISO 178 | 2mm/min | MPa | 240 | |

| Flexural Modulus | ISO 178 | 2mm/min | MPa | 7700 | |

| Notched IZOD Impact Strength | ISO 179 | 5.5J, 23°C | kJ/m2 | 11 | |

| Unnotched IZOD Impact Strength | ISO 179 | 5.5J, 23°C | kJ/m2 | —— | |

Thermal |

|||||

| Melting Point | ISO 11357 | DSC, 10℃/min | °C | 250 | |

| Heat Deflection Temperature | ISO 75 | 120°C/hr, 1.80MPa | °C | 230 | |

Other Properties |

|||||

| Surface resistivity | ASTM D257 | 23°C | Ω | >E12 | |

| Flammability | UL-94 | 1.6mm | Class | HB | |

| Glow-Wire Ignition (GWIT) | IEC 60695 | 2mm | ℃ | —— | |

| Glow-Wire Flammability (GWFI) | IEC 60695 | 2mm | ℃ | —— | |

| General Guidelines | Value | Unit | |||

|---|---|---|---|---|---|

| Drying Temperature | 80 | °C | |||

| Drying Time | 2~4 | hour | |||

| Maximum Moisture Content | 0.1 | % | |||

| Melt Temperature | 280~300 | °C | |||

| Mold Temperature | 60~100 | °C | |||